Three recycling schemes for traditionally difficult to recycle packaging products have been announced in recent weeks, in partnership with specialist recycling firm TerraCycle. And, the company will work with waste management firm Suez which has a 30% recycling share in Terracycle’s European activities.

Last week, Kellogg Company announced a scheme where Pringles tubes can be posted to TerraCycle using freepost labels.

The sender will be rewarded with a charitable donation for each tube which can be redeemed for the school, charity or non-profit of choice, Kellogg’s said.

Similarly, the public will soon be able to drop off their crisp packets at public access collection points around the country, or posted for free to TerraCycle for recycling by a box or envelope, thanks to an initiative by Walkers.

Both schemes are due to be launched in December.

Colgate

Last week, Colgate and TerraCycle announced the launch of a ‘Colgate Oral Care Recycling Programme’, which will enable the public to recycle any brand of toothbrush, toothpaste tubes and caps, toothbrush outer packaging, electric and battery toothbrush heads and toothpaste cartons.

People can sign up to the Colgate programme for free either as private collectors or returning the used items via a public location shown on a TerraCycle location map.

Collection points for various materials can be set up by members of the public by filling in a form on TerraCycle’s website.

TerraCycle said it rewards shipments of over 200 grammes of oral care products/packaging with ‘TerraCycle points’. TerraCycle points equate to a donation to a school, charity or non-profit of the sender’s choice.

‘Fudge’

Despite what some see a positive move by manufacturers to tackle complex packaging, the initiative by Kellogg’s has been challenged by the Recycling Association.

Responding to the announcement, Simon Ellin, chief executive of the Recycling Association, described the scheme as “a fudge that doesn’t solve the issues”

Mr Ellin said: “The reality is that Pringles cans are still a nightmare to recycle despite this announcement. The solution to turn them into pellets to be used in benches and fence posts isn’t circular by reusing the plastic again in the packaging. Plus, Kellogg’s hasn’t mentioned what is happening to the paper and metals that make up the majority of the packaging.”

However, in a recent statement Kellogg Company said it has recently expanded its Global Sustainability Commitments to include a goal of working toward 100% reusable, recyclable or compostable packaging by the end of 2025.

And, Kellogg’s said it has also been actively working with its suppliers to identify packaging designs that minimise waste.

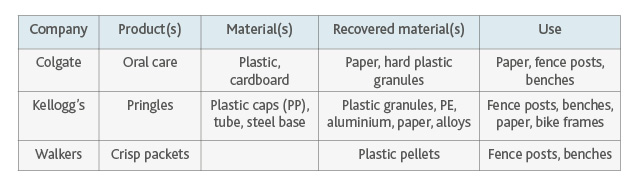

Below: A table showing materials collected and recycled under the recently announced initiatives with TerraCycle

How the various materials are recycled (provided by TerraCycle):

1. Pringles

Cans are crushed to separate the components – plastic caps (PP), tubes (paper, aluminium and PE) and base (steel). The caps are shredded, washed, dried and pelletized before being used to manufacture new plastic products such as fence posts and benches. The tube material is pulped to separate the PE / aluminium and the paper. The PE / aluminium is then pelletised and used to manufacture the likes of fence posts and benches. The extracted paper pulp is used to make new paper. And the steel bases are sent for melting into new alloys such as bike frames.

2. Crisp packets

Once the packets have been collected they will be cleaned, shredded and turned into small plastic pellets which will then be converted into useful plastic items, such as benches and fence posts.

3. Oral care

The parcels are weighed, scanned and the contents (toothbrushes, toothpaste tubes and caps, toothbrush outer packaging, electric and battery toothbrush heads and toothpaste cartons) are sorted and aggregated in bulk bags or bales.

The cardboard toothpaste cartons are used to make new paper. Plastic is shredded, washed and sorted. The material is then dried, compounded and pelletized into hard-granulated plastic granules. The granules are then incorporated into the production of different plastic products such as fence posts and benches.

TerraCycle

TerraCycle describes itself as an “innovative recycling company that has become a global leader in recycling typically hard-to-recycle waste”. The American company launched in 2009 and its UK operations are based in west London.

The post TerraCycle teams up with producers on complex packaging appeared first on letsrecycle.com.